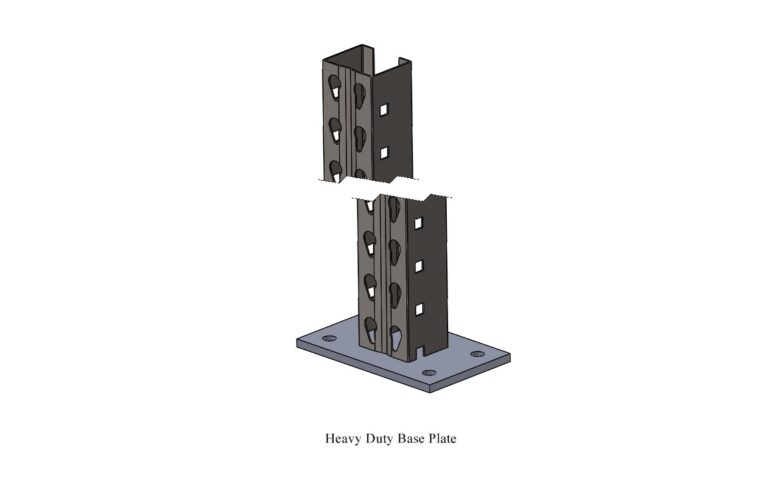

Pallet Racks are a type of shelving system designed for the efficient storage of palletized goods. They typically feature horizontal beams and vertical upright frames, creating a framework for the storage of items on pallets. These racks are known for their durability and versatility in warehouse and industrial storage applications. A pallet rack storage system is engineered with a modular and robust design. The system employs a selective rack configuration, allowing for direct access to each palletized load. Vertical uprights, composed of high-strength steel, provide structural support, while horizontal beams facilitate the creation of multiple customizable height shelf levels for pallet placement. The vertical beams are punched every 2 inches to allow flexibility when designing how much space in between the horizontal shelf levels you want. Beam connectors and safety features are integrated, ensuring stability and load-bearing capacity within specified limits. The system is engineered for ease of installation, with bolted connections and minimal hardware requirements.

Pallet Racks are a type of shelving system designed for the efficient storage of palletized goods. They typically feature horizontal beams and vertical upright frames, creating a framework for the storage of items on pallets. These racks are known for their durability and versatility in warehouse and industrial storage applications. A pallet rack storage system is engineered with a modular and robust design. The system employs a selective rack configuration, allowing for direct access to each palletized load. Vertical uprights, composed of high-strength steel, provide structural support, while horizontal beams facilitate the creation of multiple customizable height shelf levels for pallet placement. The vertical beams are punched every 2 inches to allow flexibility when designing how much space in between the horizontal shelf levels you want. Beam connectors and safety features are integrated, ensuring stability and load-bearing capacity within specified limits. The system is engineered for ease of installation, with bolted connections and minimal hardware requirements.